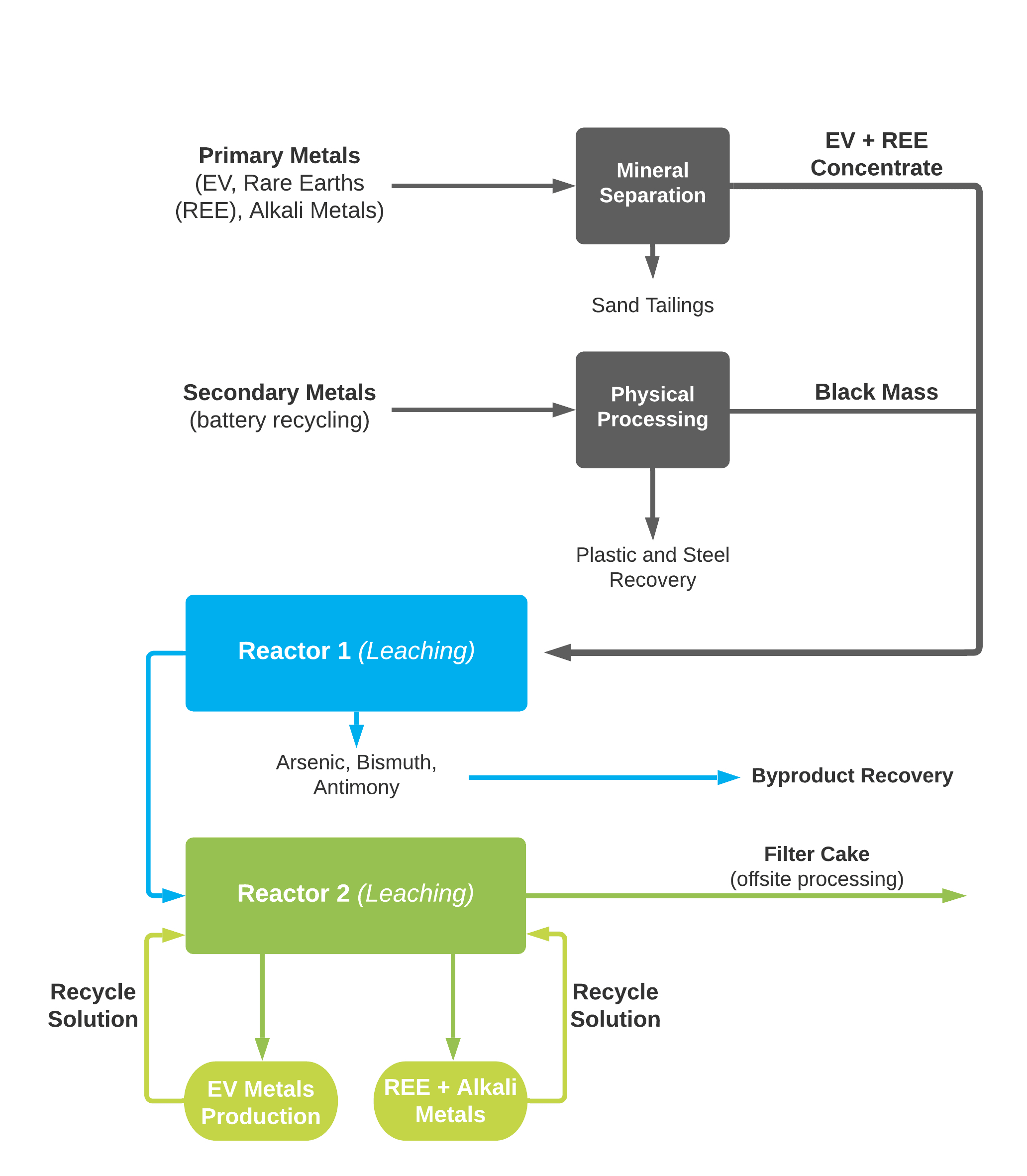

The Re-2Ox Process

Critical metals for a cleaner world

An end-to-end, zero discharge process that produces low-carbon metals pure enough to be used in batteries.

Watch the latest interview

Reasons why we are Outcome Independent

Adjustable

We can take various types of feed

Adaptable

We can perform more or fewer steps

Modular

We can work with other processes

Viable

We don't depend on public subsidies

Battery Metals

For a Clean Energy Future

Batteries offer the best chance at transcending fossil fuel dependence. But this only works if reliable supply can be secured.

Recent volatility in commodity prices underscore the imperative of diverse sources and methods for acquiring critical materials.

500%

increase in Nickel and Cobalt prices by 2050, according to the World Bank.

350%

rise in Copper demand by 2050 from research at Global Environmental Change.

Rare Earth Elements

Of Increasing Importance

The rare earth elements occupy a niche space in the global supply chain by enabling performance enhancing benefits to many consumer and industrial products.

Sodium-ion batteries

The electrolytic solution uses rubidium and cesium.

Solar power

High efficiency cells benefit from rubidium salts.

Spacecraft

Ion engines use rubidium to improve propulsion.

Byproduct Recovery

Putting Circularity First

Innovative research continues to aid in repurposing materials once regarded as waste.

Arsenic

Agricultural products, and semiconductors

Bismuth

Medical products, and the automotive sector

Antimony

Residential construction, and storage batteries

Why is hydrometallurgy better than other methods of recycling?

The hydrometallurgical method of battery recycling is unique because it does not contaminate the environment either through atmosphere, water, or leftover waste. What would otherwise have been wasted can be recovered and reused again.

Why aren't more batteries being recycled?

Batteries on the market today vary significantly and do not combine into a stream of material ready to be recycled. Therefore the challenge is to find a way to amalgamate a diversity of battery streams so they can be recycled on a greater scale.

When will batteries be made from all recycled materials?

The template for a circular economy in recycling already exists. Lead Acid batteries rely almost entirely on recycled material to manufacture new batteries. The same could be accomplished for the materials in both current and future battery chemistries

What materials will future batteries be made of?

With broader use of batteries, and volatility of prices in materials, there is an acute need to develop a new chemistry. Aside from performance measurements, new batteries must lower material costs, and be sustainable to produce. Certain chemistries have shown promise, but much remains uncertain.

Frank Basa

Founder

Recycling batteries alone is not cost-effective. That's why we initiated a tolling process to appeal to the incumbent collection bodies who want to retain ownership of the metal, while we only provide them with a service.

Adapting to the New Reality

Company founder and CEO Frank Basa, P.Eng., a metallurgical engineer and mill expert, has worked with treatment of complex ores for over 30 years. During that time, the Re-2Ox process was conceived and perfected on a variety of feed types to produce client-specific end-products.